Model: BZJ-25

Model: BZJ-25

Capacity/D: 25T

Raw material: Crude oil, Waste oil, Fuel oil, Used engine oil

Heating material: Oil, LPG, Natural Gas, Wood, Coal,etc

Structural form: Vertical

Oil yield rate: 80%-90%

Power: 138KW

Operating pressure : Normal and Vacuum

Cooling mode: Water Cooling

Life time: more than 7 years

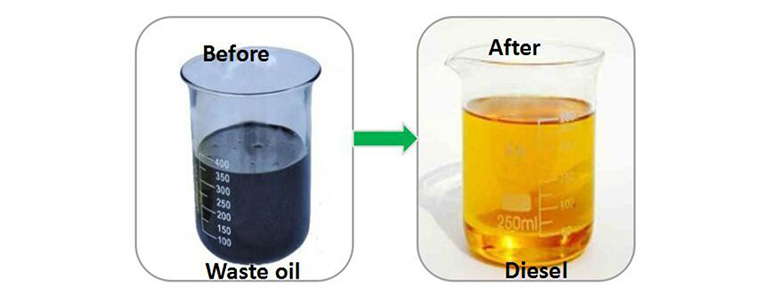

Pyrolysis plays an important role in reducing pollution of the environment. Through pyrolysis process, we can effectively convert waste tyre/plastic into useful resources-fuel oil, but in order to make the fuel oil have wider applications and higher values, we can further process the fuel oil by using the waste oil to diesel plant. Tire oil to diesel refining machine from Beston has exported more than 30 countries and regions. It can turn tires oil and plastic oil into diesel and gasoline by distillation technology.

BZJ-25 waste oil to distillation machine, Capacity 25MTPD, which has introduced tubular furnace, which improve the safety performance of production and heating efficiency. High process yield, the raw material (like used engine oil)recovery is more than 90%when the water percentage is less than 5%. High on-stream efficiency without corrosion, fouling, coking.Continuous running for 24 hours per day, auto feeding and slag discharging.

The process of waste oil to diesel plant:

The oil will first be pumped into the reactor and then it will start to boil and evaporate when it is heated to the working temperature. Oil gas from reactor has already been purified by distillation tower before it gets into condensers and liquefied into light fuel oil. This kind of oil will be piped into deep purifying systems with acidity and alkaline cleaning devices as well as pressure filtering system. When the whole distillation process is over, we will get qualified diesel oil or gasoline, the performance indexes (density, viscosity, acid value) of which can meet new standard data.

Environmental protection

1.In the dedusting system, three steps are used to dedust the hot smoke from reactor, which ensures the released gas is pollution-free

2.The exhaust gas will be directly recycled for heating reactor, no gas pollution

3. All parts are well-sealed, so air leakage can be avoided.

Safety

1.Hydroseal and Vacuum system will prevent exhaust gas from going back to condensers and reactor.

2.Equipped with thermometer, pressure gauge, safety valve and electric control system.

Note:

As we all known, oil resource is the most valuable resource in the world.So people have researched and developed pyrolysis plant converting scrap tires to tires oil. But purity and color of tire oil cannot meet the standard for cars, and it cannot be used for cars directly. So distillation technology is emerged, if you also want to disposal waste oil, please Click Here to let us have a communication.

Parameters data of Waste Oil to Diesel Plant:

| Batch Operating Plant | Auto Continuously Operating Plant | ||||

| Model | BZJ-06 | BZJ-10 | BZL-25 | BZL-50 | BZL-100 |

| Raw material | Crude oil, waste oil, fuel oil, | Crude oil, waste oil, fuel oil, | |||

| used engine oil | used engine oil | ||||

| Structural form | Vertical | Vertical | Vertical | Vertical | Vertical |

| 24-hour handing | 6MT | 10MT | 25MT | 50MT | 100MT |

| 24-hour oil yield | 5.1 MT | 8.5 MT | 21.25 MT | 42.5 MT | 85 MT |

| Operating pressure | Normal and Vacuum | Normal and Vacuum | |||

| Heating material | Oil, LPG, Natural Gas, Wood, Coal,etc | Oil, LPG, Natural Gas, Wood, Coal,etc | |||

| Power | 20kw | 36kw | 138kw | 178kw | 178kw |

| Model of cooling | Water cooling | Water cooling | Water cooling | Water cooling | Water cooling |

Application of end product:

We can get diesel oil with high purity after refining by distillation machine, this kind of oil can be used for tractors, trucks, ships, and diesel oil generator etc.