In 1983, Graham Quick, an American scientist, successfully applied methyl ester of flaxseed oil prepared by transesterification reaction to diesel engine for the first time, and proposed the concept of biodiesel, which was defined as renewable fatty acid monoester. Biodiesel can be mixed with petrochemical diesel in any proportion. It is a good substitute for petrochemical diesel, and there is no need to make any changes to the diesel engine. It provides a possible way to solve the current dual crisis of energy and environment.

In chemical essence, biodiesel is generally monoalkyl esters of C12, C14, C16, C18 and C22 fatty acids, which can be produced by transesterification or esterification of animal and vegetable oils (including waste oils) and short chain alcohols (methanol, ethanol, etc.). Petrochemical diesel is usually composed of different hydrocarbons, such as alkanes, naphthenes or aromatics. The number of carbon atoms in petrochemical diesel is usually 10_22. In addition to having a similar number of carbon atoms, they also have similar properties. In addition to the obvious advantages of renewability and degradability, compared with petrochemical diesel, biodiesel has many advantages : biodiesel has higher cetane number, higher oxygen content and better combustion performance; sulfur content is far less than petrochemical diesel, and does not contain aromatic compounds; sulfide, carbon monoxide, hydrocarbons and particulate matter in tail gas are not fully burned. In addition, the flash point of biodiesel is higher than that of petrochemical diesel, and it is safer to transport, store and use.

Therefore, the development and promotion of biodiesel is of great significance in reducing dependence on Petrochemical diesel, protecting the ecological environment and achieving sustainable economic and social development. As a big oil importing country, the consumption ratio of diesel to gasoline is always higher than that of production. Vehicle exhaust pollution has always been the main source of air pollution in big cities. Therefore, it is of great strategic significance to vigorously promote the use of biodiesel. According to the Report on the Development of Domestic and Foreign Oil and Gas Industry issued by China Petroleum Economic and Technological Research Institute, China’s net oil imports continued to increase in 2014, about 308 million tons, and its dependence on oil has reached 59.5%. Large-scale production of alternative fuel biodiesel can alleviate China’s energy contradiction and has strategic significance for guaranteeing national oil security. Over the past decade, with the continuous attention paid to biodiesel industry in China, universities, research institutes and enterprises have carried out research and development of biodiesel production technology, and achieved a series of important results.

Compared with European and American countries, China’s biodiesel industry developed late and started during the Tenth Five-Year Plan period. Some private enterprises mainly used traditional chemical methods to produce biodiesel from waste oils and fats. In 2001, the first biodiesel plant invested by Hainan Zhenghe Bioenergy Company was put into production in Wu’an, Hebei Province, announcing that China’s biodiesel industry has begun to enter the process of industrialization. In 2004, the Ministry of Science and Technology launched the “Biofuel Oil Technology Development” project of the “Tenth Five-Year Plan” of the National Science and Technology Research Program, and incorporated the related research topics of biodiesel. Since then, China’s biodiesel industry has entered a stage of accelerated development, and a large number of enterprises have actively built biodiesel projects with capacity of tens of thousands of tons per year. In addition to utilizing waste oils and fats, a woody oil plant planting base has also been set up. In 2007, the National Development and Reform Commission approved three demonstration projects of small Tung biodiesel industrialization in three major oil companies, PetroChina, Sinopec and CNOOC, with annual production capacity of 5_60,000 tons. In the same year, China also took an important step in the formulation of biodiesel standards. The first national standard “Diesel Engine Fuel Blending and Biodiesel B100” was promulgated. In 2010, the standard “Biodiesel B5” was promulgated. Since its publication, the two standards have been revised in 2014, adding a number of technical indicators, gradually approaching the European and American standards. At the same time, China’s biodiesel market has also promoted the healthy development of China’s biodiesel industry. In 2011, in order to further promote the healthy development of biodiesel industry, China issued a preferential policy for biodiesel enterprises, stipulating that enterprises that produce biodiesel mainly from waste oils such as sewage oil shall be exempted from fuel consumption tax. In 2014, the fourth batch of pilot projects on resource utilization and harmless treatment of kitchen waste has been carried out in China. A total of 83 cities have been included in this work, which has improved the shortage of biodiesel oil raw materials to a certain extent.

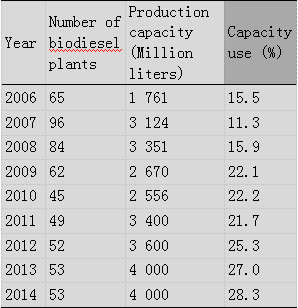

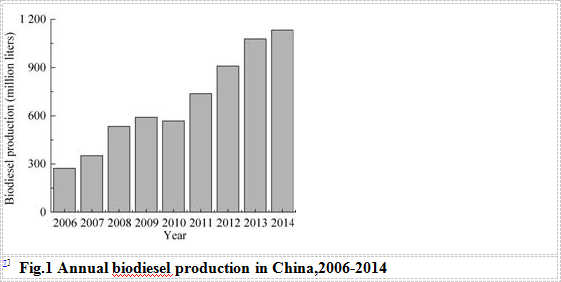

Figure 1 shows China’s biodiesel production from 2006 to 2014. In the past three years, thanks to striking the reflux table phenomenon of gutter oil and strengthening the supervision of waste oil recovery, the production of biodiesel in China has been significantly improved. In 2014, China’s biodiesel production reached 1.13 billion litres, an increase of 5% compared with 2013. At present, there are 53 biodiesel production factories in China, with a capacity of about 4 billion litres. However, compared with the production capacity and output (Table 1), the utilization rate of biodiesel production capacity in China has been relatively low over the years, less than 28%, which is mainly due to the shortage of oil raw materials and limited product sales. At present, China has not compulsorily incorporated biodiesel into the sales system of refined oil, so the vigorous development of biodiesel industry in China still needs to be further improved and strengthened by the national supervision and support.

Table 1 The annual number of biodiesel plants and capacity utilization in China,2006-2014